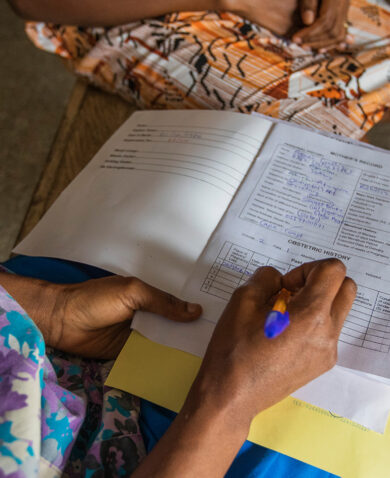

In 2011, Pharma introduced an electronic supply chain management tool — the eSCM — to improve the accuracy and timeliness of information, make ordering easier and faster, and improve communication and coordination among supply chain stakeholders. Since the eSCM launched, 96 percent of all service delivery points are using it.

The eSCM has dramatically sped up data collection and dissemination for Kenya Pharma’s staff and private sector partners, including transporters, hospitals, and warehouses, allowing them to meet patients’ medical needs as quickly as possible. With more accurate and timely data, Chemonics and USAID are also able to analyze trends, promote inventory management, and identify and correct discrepancies in data uploads, all of which create a more effective and sustainable supply chain.

Though the eSCM met a critical need in the Kenyan pharmaceutical supply chain, its development was not always smooth. The first version of the system was developed by an international firm with little input from end users, and as a result, they did not use it. Through an iterative process that involved all stakeholders throughout its development, however, Pharma built a new system that has been embraced by nearly all of the project’s service delivery points.

Go local. In this case, because so much of the system depended on usability and real-time accessibility, using a local firm brought a depth of understanding to the project. The local firm was better positioned to respond to connectivity issues and work directly with stakeholders.

Begin with the end (user). Beginning with the end user’s needs allowed the revamped system to catch on more quickly with key groups. End users’ input on functionality greatly informed design, and involvement in the process gave users a sense of ownership over the system.