3 Questions with Tom Brown on Championing Innovation in Health Supply Chains

June 20, 2023 | 3 Minute ReadChemonics’ principal advisor for supply chain management talks about health supply chain innovation, the opportunities it creates, and its role in building resiliency.

1. What drew you to work in health supply chains?

1. What drew you to work in health supply chains?

I started out working in supply chain projects in the National Health Service here in the United Kingdom and did that for two years before getting opportunities to work on projects overseas. I’ve now been working in health supply chains in low- and middle-income countries (LMICs) for almost twenty-five years, and I really can’t think of another career path that I would rather have chosen over this one. Supply chains are endlessly fascinating things, which require us to think in a few different ways to get them right. We need to learn and apply statistical techniques that help us to design and manage supply chains that can satisfy demand. We need to understand complex systems and think carefully about how each part of the supply chain affects the others. We also need to understand the human aspects of supply chains and dig deeply into why people working in supply chains do things in certain ways. When we blend all these things together well, we give ourselves a great chance of doing strong work and making a real difference to the patients and consumers who rely so much on what we do. All of us who work in this field and get the chance to address these problems day in and day out are tremendously fortunate.

2. The past couple of years have presented many challenges for health supply, but they also drove innovative solutions. Can you share with us what you’ve learned about introducing innovations during your career?

In my experience, innovations are far more likely to succeed if they’re introduced under a few basic conditions. We need to have a defined and measurable problem, a clear understanding of how we expect the innovation to make a difference, and the skills and capacity to absorb the innovation into our way of doing things. A few years ago, I led a team that introduced a quality management system (QMS) to a central medical stores organization, which was an innovation in that particular context. One thing that surprised me was how many new ideas then came out of the regular performance reviews – the QMS principles forced us into a regular rhythm of analyzing performance and thinking of ways to improve that performance. So, the ideas always flowed from that clear understanding of the problem that we were trying to solve. Up until that point I’d not considered that something as structured as a QMS could drive creative thinking to that extent.

3. What do you think the future of health supply chains looks like? What will be the biggest priorities to ensure supply chain systems can respond to future shocks and crises?

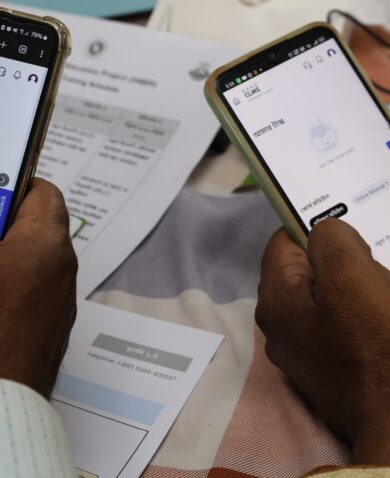

Technology is, and will continue to be, the biggest driver of change in health supply chains. Over the last decade or so we’ve already seen an explosion of new tech-based tools that improve the capture, transmission, analysis, or use of supply chain data. All of this opens up new opportunities for us to understand demand better and offer access to critical products in more convenient and tailored ways for users. Future health supply chains in LMICs are likely to be serving customers through a more complex network of health service points than is currently the case, especially in countries moving towards mixed public and private delivery models, so these tech advances will be critical in making all that work efficiently.

As for preparing for future shocks and crises, I think much of that depends on those who control the purse strings. We saw during the COVID-19 crisis how much we had all focused on cost and efficiency in our supply chains at the expense of resilience. If we want to prepare properly for the next pandemic or other shock, we will need to accept that building the necessary redundancies into our supply chains will come at a premium. We will likely need multiple different strategies at once, including some that target inventory (such as stockpiles) and those that target capacity (like developing new, diversified lines of supply).

Banner photo: Peng Seang inspects products at the Siem Reap warehouse facility in Cambodia. Credit: Chris Norman for Chemonics.

Posts on the blog represent the views of the authors and do not necessarily represent the views of Chemonics.

1. What drew you to work in health supply chains?

1. What drew you to work in health supply chains?