The Beninese government was keen to develop local expertise to conduct safe and environmentally responsible pharmaceutical waste management in-country. In 2017, it began collaborating with USAID’s Global Health Supply Chain (GHSC) – Technical Assistance (TA) Francophone Task Order, implemented by Chemonics, to build local service providers’ capacity.

Professor Fernand Gbaguidi, director of the Ministry of Health’s Directorate of Pharmaceuticals and Laboratories, reiterated that building local capacity gives the Beninese government multiple ways to address pharmaceutical waste management to assess the most efficient, cost-effective approach for each case.

Destroying pharmaceutical waste typically involves making the hazardous waste inert, or inactive. Mixing the waste with cement and other substances, such as lime, makes it less likely that the toxic substances in the waste will dissolve into the groundwater — which could cause widespread health risks. Once everything is mixed together, the resulting combination creates a uniform substance, which in turn can be made into cubes or pellets that are taken to a government-approved landfill site.

Keeping this in mind, GHSC-TA worked with a waste management expert to identify a local service provider, BAB, and design a tailored training program. In addition, GHSC-TA provided a list of safety upgrades to the equipment to meet international standards, which BAB completed before the training began.

The training sessions took part in October 2017. BAB took the lead: First, the training-of-trainers brought 17 BAB staff members and two employees from the Ministry of Health to Chemonics’ office in Cotonou. This session took place at an enclosed compound, far enough from any surrounding villages to keep contaminants contained. The training-of-trainers focused on waste management guidelines for all stages — from packing to transportation, triage, inventory management, inertization, and landfill.

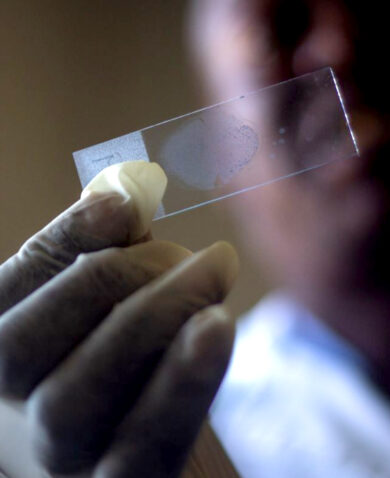

Following this first session, the 17 participants trained 30 of their peers, gathering at the sorting site of Calavi to learn how to safely and responsibly destroy pharmaceutical waste. The trainer demonstrated how to properly remove the packaging materials, paper, cardboard, and plastic from the pharmaceuticals. The trainees practiced removing pills from their blister packs, and learned how to grind the pharmaceuticals and mix them with water, cement, and lime to form a homogenous paste. After completing the training, BAB staff successfully destroyed the 118 tons of seized counterfeit medicines.

Dr. Corneille Capko, pharmaceutical advisor at the Ministry of Health and one of the trainees, was amazed by the level of safety and security measures, especially the personal protection equipment, required by the GHSC-TA project to adhere to minimum safety standards. He also appreciated the project’s rigor in ensuring that capacity building took place via a formal training with certificates in waste destruction and counterfeits’ strict inventory guidelines.

Destroying those 118 tons hardly solves the entire counterfeit medicine problem in Benin, but it was a critical step forward. The country now has the capacity to conduct similar pharmaceutical waste management activities in the future, speeding up the process and making it that much more difficult for fake drugs to remain in circulation.