3 Questions with Gaspard Harelimana on Enhancing the Health Supply Chain in Rwanda

February 17, 2023 | 3 Minute ReadWe talk with Gaspard Harelimana from Rwanda Medical Supply to learn about how the Quality Management Improvement Approach is building a stronger health workforce and improving Rwanda’s health supply chain.

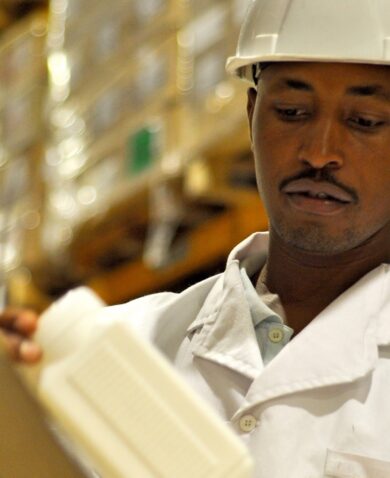

Following the publication of the article, “The Quality Management Improvement Approach: Successes and Lessons Learned From a Workforce Development Intervention in Rwanda’s Health Supply Chain” in the Global Health: Science and Practice journal, we talked with Gaspard Harelimana, Assistant Regional Warehouse Manager with Rwanda Medical Supply (RMS), to learn more about improvements to Rwanda’s health system. RMS, a key partner of the Chemonics-led USAID Global Health Supply Chain Program-Procurement and Supply Management (GHSC-PSM) project in Rwanda, is a large-scale corporation owned and created by the Government of Rwanda to ensure the availability of medicines and health commodities and overcome challenges of low availability at the public central medical store. His background in pharmacy and more than 10 years of experience in supply chains have afforded him an insightful perspective on the health system in Rwanda.

1.Could you please provide a brief overview of the implementation of the Quality Management Improvement Approach (QMIA) and GHSC-PSM’s involvement in it?

Rwanda’s Ministry of Health (MOH), through RMS, and GHSC-PSM implemented a workforce development intervention, known as the Quality Management Improvement Approach (QMIA). The QMIA was aimed at continuously improving supply chain performance through the availability of medicines, capacity building, and data quality assurance to sustain Rwanda’s service delivery and medicines availability. The QMIA monitors the performance of supply chain professionals while continuously building their capacity to run a smooth supply chain operation. This includes supervisory visits with pharmacies and service delivery points aimed at measuring key performance indicators and facilitating discussion sessions for experience-sharing and skill-building among staff. The central level conducts both components of the QMIA approach, supporting regional warehouses that in turn assist service delivery points through supervisory visits and discussion sessions. GHSC-PSM’s involvement is focused primarily on procurement of health commodities and delivering technical assistance by supporting the MOH in strengthening the last-mile workforce development.

2. What were some of the main supply chain challenges at RMS warehouses? How did the QMIA approach address them?

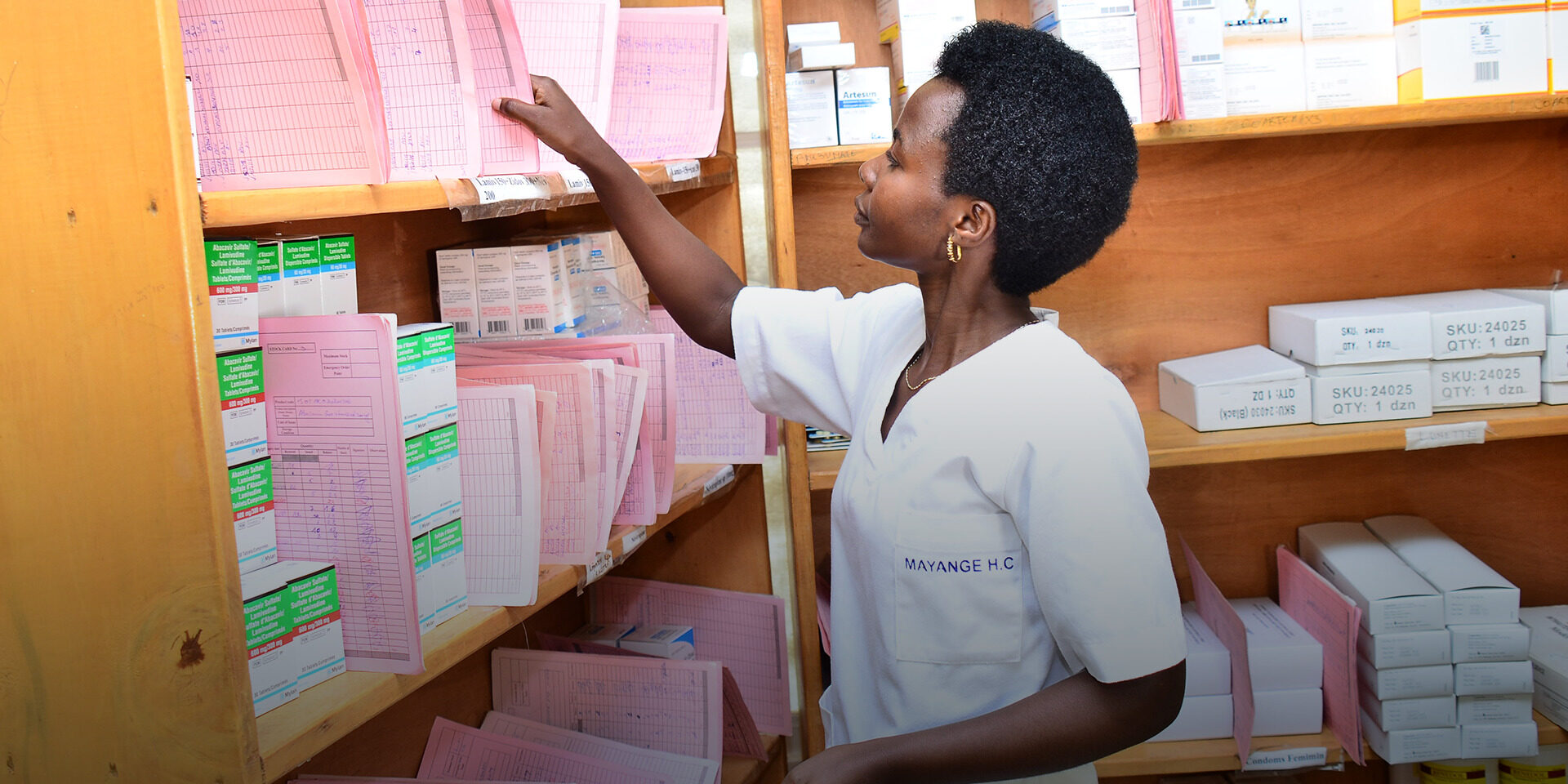

The main challenges we experienced included poor data quality from our health facilities, poor quantification of medicines leading to shortages or overstocks, and underutilization of the electronic logistics management information system (e-LMIS). These operational challenges stemmed from larger problems with the supply chain workforce, such as high staff turnover, not enough staff at service delivery points, and lack of capacity for existing staff to perform additional supply chain activities.

The QMIA approach was used to implement a workforce development intervention that improved supply chain professionals’ performance, with the intended outcome of improving data quality for operations. With support from GHSC-PSM, the 30 RMS branches conducted supervisory visits and discussion sessions at 596 service delivery points throughout the four years of the intervention. These visits focused on continuous capacity-building of staff to perform supply chain reporting activities through mentorship, supervision, and performance improvement through measurement of key performance indicators. Investing time and money into developing the supply chain workforce has significantly improved the availability of essential medicines and reduction of wastage at RMS warehouses. Overall, the QMIA has proven to be a successful training and capacity-building platform for supply chain management in Rwanda.

3. What changes did the QMIA have on operations at RMS and what was their impact on the health supply chain in Rwanda? Could you provide an example or story that illustrates this impact?

The 30 RMS branches located in 30 districts (1 RMS branch per district) play a key role in storage and inventory management, transportation of commodities to health facilities, resupply, and support to and supervision of service delivery points within their respective districts. One of the changes that the QMIA approach brought our operations was to remove routine work and build on existing technological innovations. For example, some store managers were resistant to using the Information and Communication Technology (ICT) equipment, especially software, such as the e-LMIS, because they were used to recording data manually. However, through continuous training, RMS staff are now efficient in using ICTs while recording logistic data. Utilization of the e-LMIS increased from 55% to 96% throughout the QMIA. Accurate and real-time data is now visible across all supply chain levels in Rwanda due to increased use of the e-LMIS.

Posts on the blog represent the views of the authors and do not necessarily represent the views of Chemonics.

Photo caption: A woman pharmacist in Rwanda stocks a card shelf. Credit: GHSC-PSM