Looking at the market for O2 commodities, there are very few manufacturers that can produce these lifesaving commodities that meet the defined quality standards. By having a thorough contracting and selection process, we were successful in identifying appropriate suppliers with strong in-country service representatives to not only ensure the successful installation and commissioning of equipment and training of facility staff on safe-use of oxygen generating equipment such as PSAs and oxygen concentrators, but also, and more importantly, that the equipment is maintained according to manufacturer recommended standards and guidelines. The supplier relationship is essential to the sustainability of the equipment.

Related particularly to the more complex PSA plants and bulk liquid oxygen, GHSC-PSM has played a pivotal role at the country level ensuring extensive coordination, working closely with USAID/Washington, Missions, suppliers, and in-country partners and stakeholders. This has not only been key to the successful deployment of the equipment but also tantamount to the overall success of the oxygen program to date.

Then, engaging with the host country government is also critical. We need to know that our in-country stakeholders are confident that the equipment meets their needs, they understand how the product operates and have their sites ready to receive the PSAs to install and commission the equipment, and staff are trained to be able to operate them safely. Their commitment is vital to in-country success.

3. What is a successful innovation or outcome you can share from this project thus far?

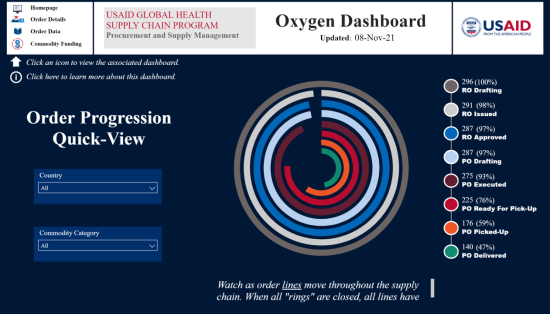

The O2 activity developed an innovative tool that was initially piloted by a [GHSC-PSM] COVID-19 procurement initiative started in 2020. We call it our “Oxygen Dashboard.” It has been a gamechanger in terms of enhancing end-to-end visibility of our order fulfillment under the oxygen activity.

The dashboard presents [supply chain] data from our in-house management information system – ARTMIS – in a user-friendly format. The tool includes pertinent details of every order line for each country and commodity type. We can see progress of the current 300 order lines, where we are throughout the order fulfillment stages all the way to delivery. In addition, we track expenditures against funding ceilings by country at the same level and granularity and, with a financial lens, track our progress against our programmatic objectives. When we have experienced upstream manufacturing delays and freight cost changes, we can stay current with this tool. We have provided broad access to our USAID counterparts to view this information which they use consistently.

Posts on the blog represent the views of the authors and do not necessarily represent the views of Chemonics.

Banner image caption: Procurement Specialist Ellen Airozo (left) and Oxygen Deputy Team Lead Markos Layton (right) stand in front of oxygen equipment at Airsep manufacturing facility in June 2021.