Kenya Pharma has seen numerous benefits from using an ISO 9001 approach for supply chain management. Some of these include:

- Since QMS implementation, the average time for sea and air shipments to clear customs decreased from 21.8 days to 5.7 days for sea shipments, and from 2.5 days to 1.8 days for air shipments.

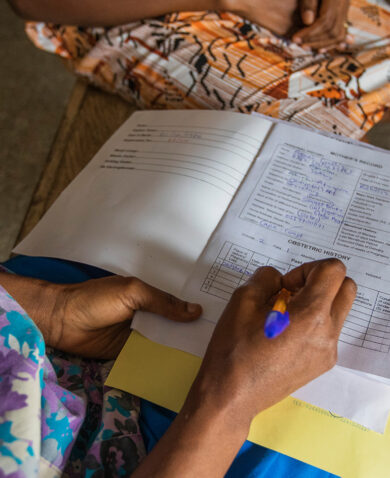

- The percentage of health facilities passing supply chain data quality audits increased from 53 percent to 68 percent, and significant improvement was seen in the project’s performance forecasting future costs to manage and operate the supply chain.

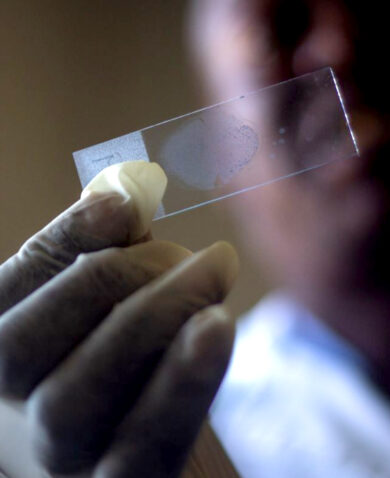

- World Health Organization (WHO) treatment guidelines and a series of industry-wide technical standards in procurement, distribution, and warehousing, were purposefully woven into the Kenya Pharma Quality Management System (QMS) processes to ensure the supply chain was in compliance, and all industry and technical requirements were captured and reinforced by the QMS.

- With the QMS as a centralized, but flexible, and ever-improving system, the project can now push out information and updates faster to remote Field Service Representatives (FSRs) who work around the country–in some cases in very remote locations–serving as the direct liaisons between the project and the clinics and hospitals they serve.